(주)누리케미칼을

방문해 주셔서 감사합니다.

EH 병원 방문을 환영합니다.

궁금한 점을 검색하세요.

Cleaning Machine

- Home

- Cleaning Machine

- Ultrasonic Unit

Cleaning Machine

Ultrasonic Unit

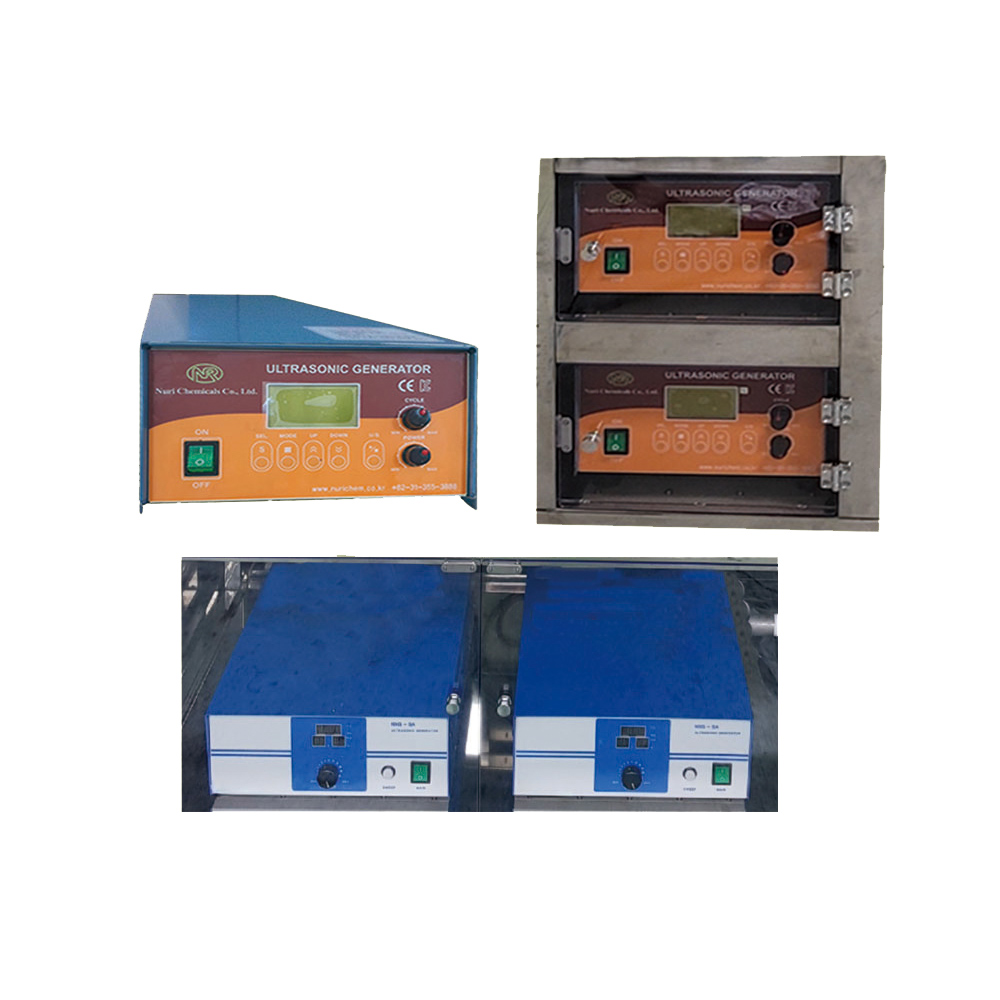

Ultrasonic Generator Part

Feature : Device that generates ultrasonic waves and is mainly used in medical diagnosis and industrial use, and the principle is as follows

1. Ultrasonic generation or a special ultrasonic delivery gel (material to reduce noise attenuation) is used to transmit ultrasonic waves between the object and the ultrasonic

Ultrasonic cleaning begins with the generation of ultrasonic waves in the ultrasonic generator. Ultrasound is a high-frequency sound Ultrason that the human ear cannot hear

2. Ultrasonic transmission

Ultrasound generated by the ultrasonic generator is transmited to the target object through a transmission medium. In most cases, watergenerator

3. Propagation of ultrasonic waves

ic waves propagate to the surface or inside of a target object. They reach every part of the target object, and this causes periodic changes in compression and weakness

4. Pressure difference and amplification

When ultrasonic waves reach the surface of the target object , a pressure difference occurs, which causes the particulates on the surface of the object to shake..

The movement of these particulates can remove badges, contaminants, corrosives, and foreign substances inside objects.

5. High-frequency oscillation

Ultrasonic waves are high-frequency, so they are repeatedly compressed and weakened in very fast cycles. These periodic vibrations help to easily separate and remove corrosion or contaminants from surfaces.

6. Separation of cleaned objects and contaminants

After ultrasonic cleaning, contaminants on the surface of objects fall off or separate and move to different locations of the material. These removed contaminants are typically separated through the cleaned materials and come out in a cleaned state.

7. Summary

Ultrasonic cleaning can be adjusted with various frequency, intensity, and time settings depending on the process, which is why it is used in various applications. This method is relatively efficient and is particularly useful for accessing detailed and complex areas that are difficult with chemical or mechanical cleaning.

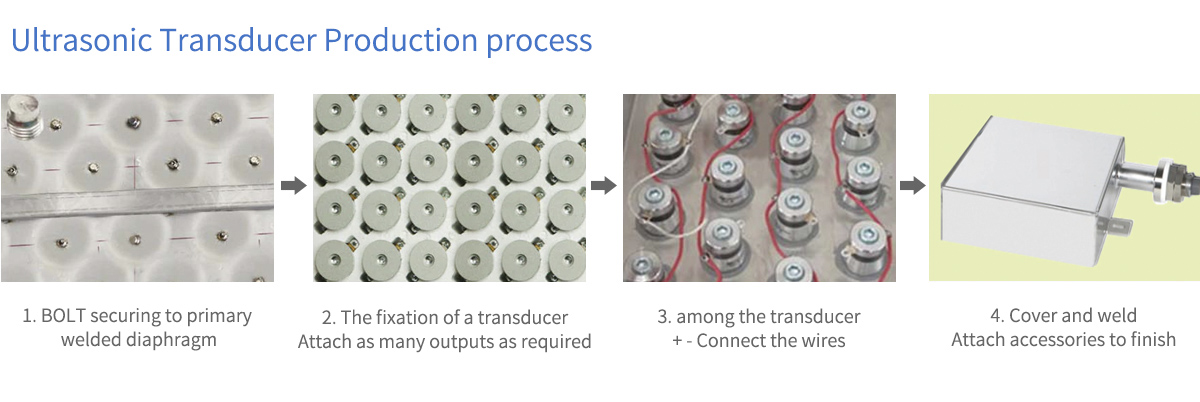

Ultrasonic Vivrator Parts

Features: device used to generate and detect ultrasonic waves, it is used in various fields such as medical diagnosis, industrial inspection, and underwater exploration. The principles of ultrasonic oscillators are as follows.

1.Piezoelectricity Relevant

The core component of ultrasonic oscillators is a special material called piezoelectric. A piezoelectric is a material that generates electrical signals under pressure or is deformed by the electrical signals. The most commonly used piezoelectric material is a ceramic material, and these ceramic materials are the main components of the oscillator.

2. Oscillation and reception processes

The ultrasonic oscillator performs two main functions. First, an electrical signal is applied to vibrate the piezoelectric element. These vibrations produce ultrasonic waves. These generated ultrasonic waves propagate to their surroundings. Then, when ultrasonic waves interact with the target object, the waves are reflected or absorbed. The reflected ultrasonic waves are returned to the piezoelectric element and converted into electrical signals. These signals are used for subsequent processing and image generation.

3. Control waveform and frequency

The waveform and frequency of the ultrasonic waves generated by the ultrasonic vibrator are adjusted according to the application field. Medical ultrasound scans use high-frequency ultrasound waveforms to image different tissue structures, and industrial scans can use different waveforms depending on the thickness or structure of the object.

4. Signal processing and imaging

The reflected signals received by the ultrasonic vibrator are processed by a computer or electronic device. These processes can provide information about the internal structure or surface properties of the object. Medical ultrasound images this information to produce ultrasound images showing the inside of the patient.

5. Summary

The ultrasonic vibrator uses a piezoelectric to convert the electrical signals into ultrasonic waves, and these waves interact with the object to generate reflected signals. These reflected signals are converted back into electrical signals and used for image generation, which can help analyze or visualize the internal structure or surface properties of the object.

Application

GLASS, LCD panel, glass container, nonferrous metal, secondary battery parts, precision mechanical parts, semiconductor parts, molds, MCT processed products, CNC processing products cleaning, glasses cleaning, jewelry and accessories cleaning oil removal, rust removal, press oil removal, paint removal, etc. can be removed even under adverse conditions

Purchasing only the ultrasonic unit and applying it to the currently used cleaning tank or purchasing the washing tank as ASS\'Y.-

* Classification according to the attachment method of the vibration unit.

1.Tank floor direct attachment type

2. Cleaning method by fixing vibrators to the side and floor inside Tank

3. Connecting the pipe to the Transducer and fixing it from the top.

Move Top